Technology to satisfy California Rule 21 and Rule 30 for RNG pipleine injection

While digesters normally require only carbon dioxide (CO2) removal from the product gas, landfills generally have issues with both CO2and nitrogen (N2) in the feed gas. Guild Associates' approach to landfill gas upgrading is flexible depending on the needs of the customer.

Guild Associates has executed dual-Pressure Swing Adsorption (PSA) systems, pairing the Molecular GateTM CO2 technology with N2 rejection. Contact Guild Associates for an equipment solution to match your needs.

This short video from the Billings Tribune details the operation of the Guild Associates dual-PSA system at the Billings, MT landfill.

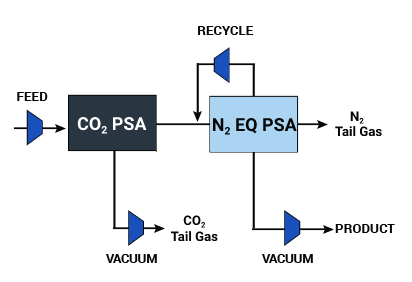

The unique dual-PSA approach results in a simplified system that is easy to maintain and operate. The feed gas is compressed then cooled in order to remove the bulk of the moisture in a condensate trap. The resulting feed gas is then re-heated using the waste heat of the compressor and fed to the CO2 PSA. The CO2 PSA utilizes the Molecular Gate adsorbent that has been pore-sized controlled to preferentially adsorb CO2, permitting the methane and nitrogen pass. In the CO2 PSA step, CO2 is removed from a typical 35% - 45% range down to less than 1%, the CO2 level is selectable by the owner/operator. Also removed in this step is residual moisture (to <150 ppm), siloxanes, volatile organic compounds (VOCs), and hydrogen sulfide (H2S).

The Guild Associates' Molecular Gate technology enables the system to be efficient, easy to operate and maintain. There is no media to replace on a regular basis, as the Molecular Gate media is regenerable and will last the lifetime of the equipment.

The product gas from the CO2 PSA is fed to the Equilibrium N2 PSA which removes the nitrogen and oxygen to pipeline quality. The resulting product gas of the N2 PSA is compressed for injection into natural gas grid. The methane recovery of the Equilibrium N2 PSA is typically better than 97%. The overall dual-PSA plant methane recovery is about 93%.

Do you have a project in mind?

Download our CUSTOMER QUESTIONNAIRE and send the completed form to Guild Associates, or alternatively use the Online Project Questionnaire below, or click here to request more information.

Guild Associates has a solution for you. Contact us to learn more.

Frequently Asked Questions About Landfill Gas Upgrading

Contact Guild Associates and we will work with you to determine the best technology for your application. To quicken the discussion, please use our CUSTOMER QUESTIONNAIRE to organize your information for the discussion.

Guild Associates' simplified designs and years of field operational experience result in a reliable and maintainable system. Contact Guild Associates for more details.

Guild Associates has test data to support the removal of all trace components including:

H2S, H2O, O2, VOCs, siloxanes, heavy hydrocarbons (C6+), and Ammonia (NH3), as well as Carcinogenic and Non-Carcinogenic Constituents identified in "Biomethane Quality Specifications" of Southern California Gas Company Rule No. 30 and Health Protective Consituents - Carcinogenic and Non-Carcinogenic listed in Table 1 of Pacific Gas and Electric Company Gas Rule No. 21.

Contact Guild Associates for a review of your site conditions and a solution to meet the challenging California requirements. Please download and fill out our CUSTOMER QUESTIONNAIRE to get us started!

EUEC2020 Cancelled, Presentations Available Here!

Dr. Joseph A. Rossin, VP of Materials Development, and Dan Moeller, Process Engineering Manager were scheduled to will speak on separate topics at EUEC 2020, the 23rd annual Energy, Utility & Environmental Conference in San Diego, California. However, the conference cancelled due to the Coronavirus Pandemic.

Dr. Rossin's presentation is entitled "BSR-050 – A Novel High-Capacity H2S Removal Media", and is available for download by clicking on the title.

Dan Moeller's presentation is entitlled "RNG: California Rule 21/30 Compliance Made Easy", and is available for download by clicking on the title.